A continuation from Always Clean Hulls – Part 1

Authors: Marciel Gaier , Ph.D. Philippos Sfiris

There are three major trends in the market right now:

Regulation is moving towards a balance between emissions to air and emissions to sea

Wider adoption of performance coatings leads to a higher amount of biocides or toxins released into the marine environment. Antifouling coatings are designed with a biocide suspended in a coating matrix which gradually releases the biocide over the service life. These ‘self-polishing’ antifouling coatings today represent a big part of the market. In recent years, there have been growing concerns over the harmful effects of these paints due to the water pollution from the release of copper compounds from their leeching working mechanism as well as the excessive discharges from repeated cleanings. The regulatory focus so far has been on the air emissions, however as more viable alternatives are emerging in the market, regulators are expected to put more restrictions on the use of biocides [3].

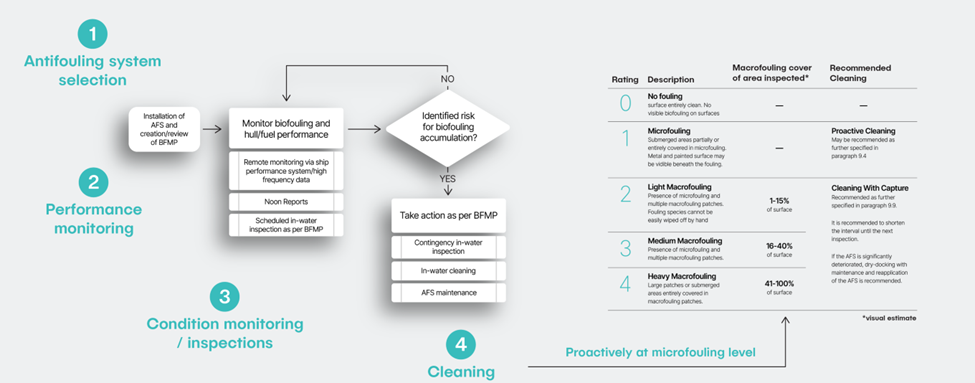

Biofouling is recognized as a major contributor for the introduction and spread of invasive aquatic species that can reduce ship performance, increase fuel consumption and greenhouse gas emissions. The IMO’s Biofouling Management Guidelines [4] provide an international standard to address this. The guidelines emphasize the need for constant monitoring of biofouling with frequent inspections and recommends proactive cleaning (grooming) as a preventive measure, i.e. periodical removal of microfouling (slime) prior to macrofouling growth which can be conducted with or without capture.

IMO, 2023 Guidelines for the Control and Management of Ship’s Biofouling to Minimize the Transfer of Invasive Aquatic Species

While the IMO guidelines are not mandatory, several regions have restrictions in place regarding hull biofouling requiring in-water cleaning before entry or prohibiting the practice while in port. Australia, New Zealand and the US west coast are amongst those that have issued more stringent requirements.

At the same time, the International Organization for Standardization (ISO) is developing a pair of new standards for the industry which will help in the testing of the hull cleaning robots and systems that are being developed by a growing range of start-ups. One of the standards is for the actual testing of biofouling in-water cleaning systems to help ensure shipping companies that the systems, and by default the cleaning outfits they choose, are able to do the work. The other is to offer owners guidance on the process of planning and conducting cleaning operations [5].

A growing market of hull cleaning robots is emerging

In the recent years, a significant number of hull cleaning robots have been commercialized and are now being trialed by shipowners and operators. Current offerings vary in terms of the following key criteria:

-

- Cleaning while in transit or in port

-

- Level of crew involvement: A few solutions are fully autonomous operated remotely, while most are semi-autonomous and require some level of involvement from the crew in handling and controlling the unit

-

- Limitations in speed

-

- Cleaning capabilities: Cleaning with brushes, air cavitation, with capture and with no capture

-

- Coverage of vertical sides only or full hull including flat bottom

-

- Proactive Vs Reactive: Some solutions are focusing on hull grooming, where system removes slime thus preventing build up. Other solutions are focusing on reactive cleaning of hulls, i.e. removal of heavy fouling and therefore need for collection and disposal

-

- Reporting of inspections with photo/video footage that can be used for Port Authorities and Class Societies

-

- Pricing model – annual subscription (OPEX) or unit purchase (CAPEX)

Hull grooming is emerging as a proactive method to control fouling

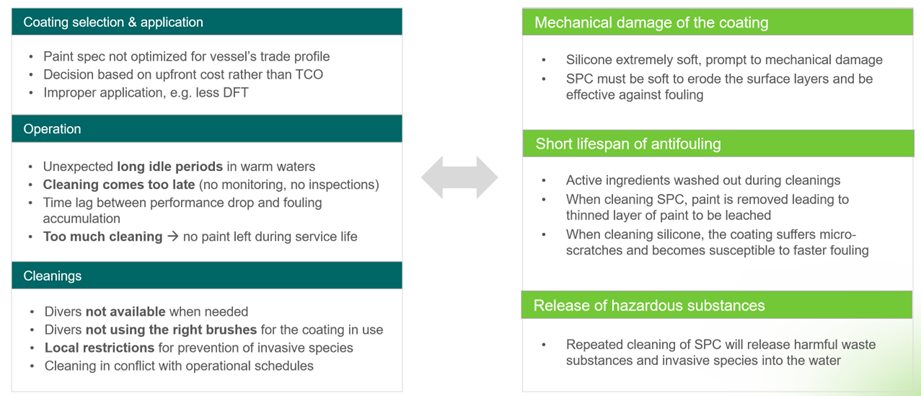

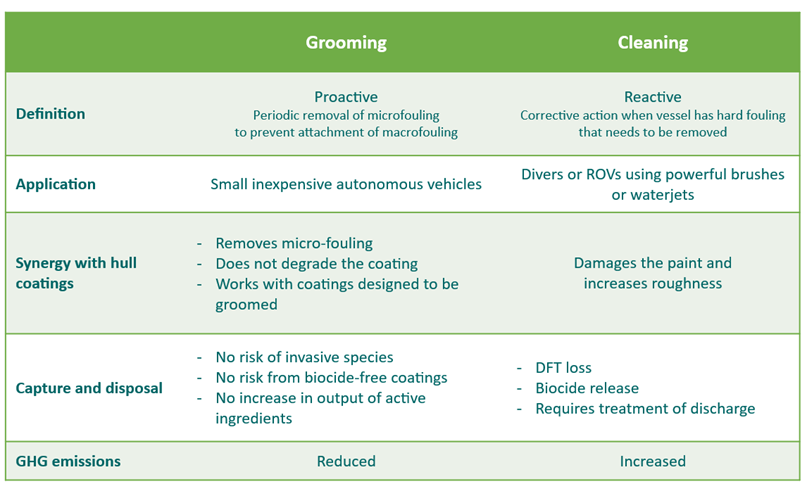

In-water hull cleaning is an important part of ship operations, however it has been typically implemented as a reactive measure when fouling reaches a critical level and requires powerful machinery which damages the coatings, shortens their antifouling property by removing part of the paint and releases hazardous substances into the water [6]. This method also increases significantly the safety risk of divers. Some of the common issues in operation and their outcome are described in the following table:

Hull cleaning is typically implemented as a reactive measure which results in paint damage and excessive discharges to the environment

The market is increasingly aware of these issues and many owners and operators are adopting a more proactive approach to control fouling with periodical removal of slime or light fouling. Hull grooming as a proactive method ensures a smooth clean hull and minimizes the risk for transfer of invasive species or excessive discharges of material that occurs during reactive cleaning. Grooming does not degrade the coating, but it should be applied to mechanically durable and biocide-free coatings that are engineered to be groomed with no risk of water pollution.

How grooming is different from cleaning, Swain et al, 2022

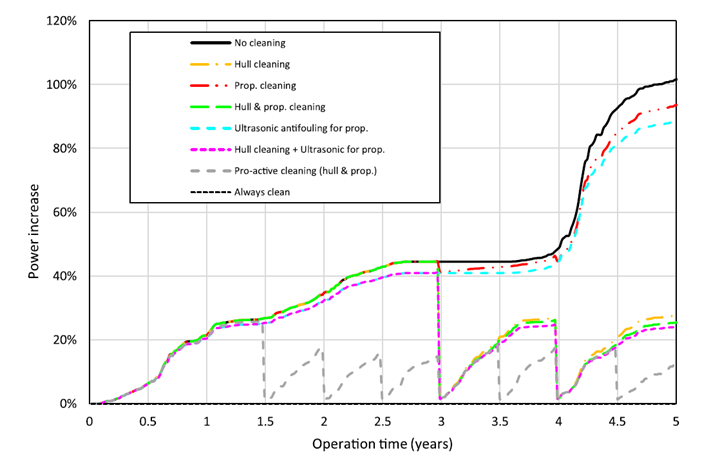

Below graph shows the % increase in the required engine power to maintain the design speed with different hull management strategies over the 5-year operation for a bulk carrier trading in Equatorial region. This simulation was done as part of the IMO’s GloFouling project and it is based on added frictional resistance coefficients (ΔCF) calculated using Granville’s similarity law scaling method based on biofouling growth predicted for different antifouling strategies. The ‘No cleaning’ scenario shows the most severe increase in the engine power up to more than 100%. Reactive cleaning, where first cleaning is triggered when the power penalty reaches 40% and rest cleanings undertaken during years 3 and 4, could result in 15% savings compared to the ‘No cleaning’ scenario. Proactive cleaning, in this case modelled 1.5 years after new coating application, showed the best performance that could entail approximately 22% savings in fuel consumption and GHG emissions.

Required engine power increase of the bulk carrier at the design speed with different anti-fouling strategies over the 5-year operation (Equatorial region), IMO GloFouling report on marine biofouling

[3] Biofouling Management for recreational boating: Recommendations to Prevent the Introduction

and Spread of Invasive Aquatic Species, GEF-UNDP-IMO GloFouling Partnerships Project, 2022

[4] Guidelines for the control and management of ships’ biofouling to minimize the transfer of invasive aquatic species (Biofouling Guidelines), IMO 2023, Resolution MEPC.378(80)

[5] Hull cleaning robots set to boost shipping in fuel-efficiency fight, TradeWinds, 2024

[6] Proactive in-water ship hull grooming as a method to reduce the environmental footprint of ships, Swain et al, Frontiers in Marine Science, 2022

Submit Below & Receive Full Article

XGIT-GROOM