Reduce hull friction to boost fuel savings and reduce emissions

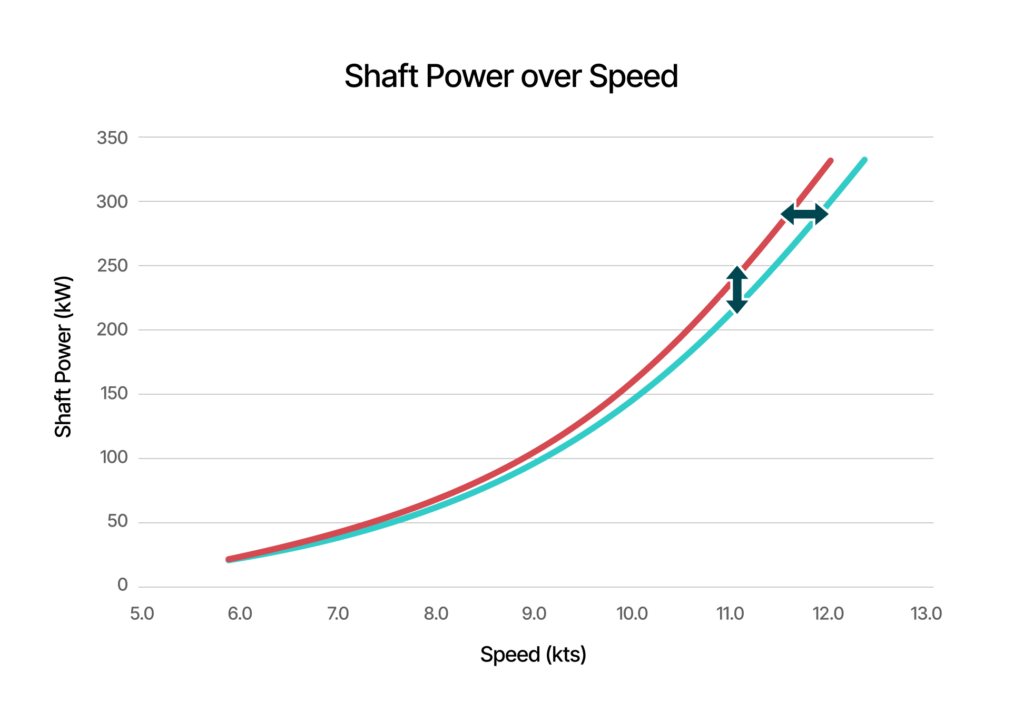

XGIT-FUEL is a graphene-based hard foul release hull coating that creates an ultra-low friction surface to increase vessel efficiency, and its patented XGIT® technology secures a hydrated layer that deters the settlement and attachment of biofouling.