Authors: Marciel Gaier , Ph.D. Philippos Sfiris

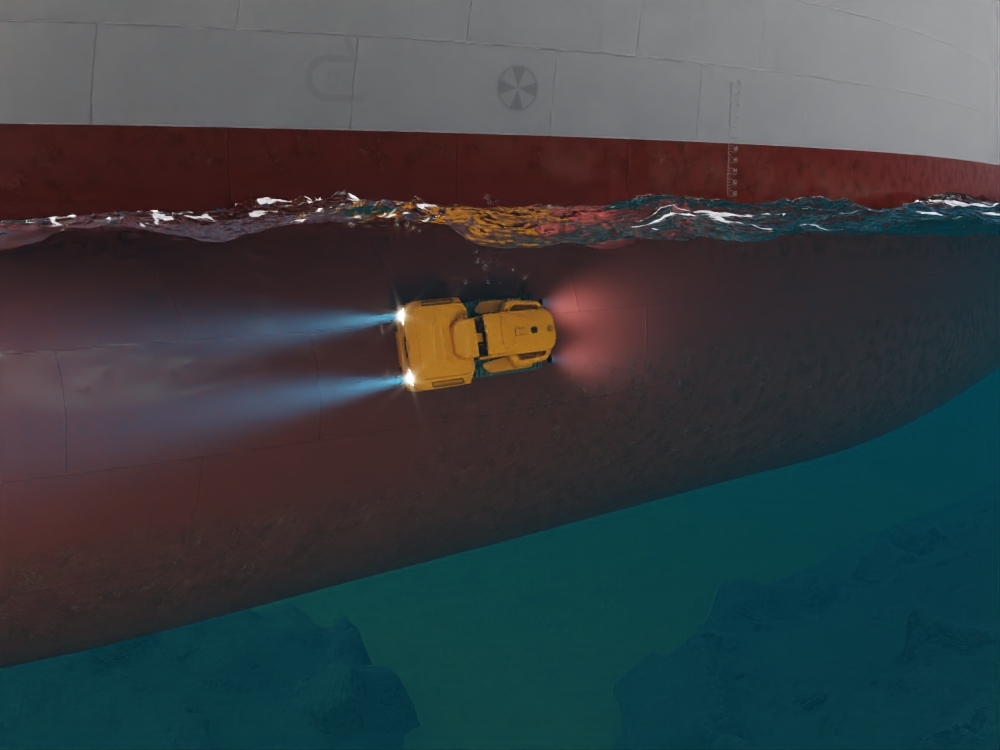

IMO is targeting for 20-30% reduction in emissions in 2030 compared to 2008 which, given a moderate trade growth scenario, translates to a requirement of 76% reduction relative to the business-as-usual scenario in 2030. Achieving this stretch target is challenging given the limited availability of alternative fuels. It is calculated that more than 30% of efficiency improvements are expected to come from energy saving technologies [1]. Especially the focus right now is on practical and proven solutions with immediate efficiency improvements that can “bridge the gap” towards green fuels and zero-carbon ships. So the hull is coming back into focus. Accounting for 20% of the structural design of a vessel, a ship’s hull has a significant impact on vessel performance and a smooth, clean hull can maximize operational efficiency. This can help shipowners and operators address IMO’s short-term measures such as the Carbon Intensity Indicator (CII), reduce fuel costs and carbon costs associated with the Emissions Trading Scheme (EU ETS) as well as improve the commercial attractiveness of their vessels.

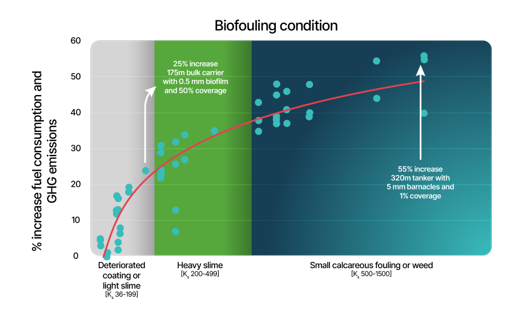

It is well documented that even a light layer of slime with 50% coverage can trigger 20-25% increase in CO2 emissions, as shown below, based on surface roughness levels linked to different biofouling types [2]. When a vessel is drydocked with a low-grade antifouling paint applied on her hull, within one year and depending on the trade the vessel may end up with 20% power increase due to the biofouling penalty. This number can go to 40% in Year 4 in the dry docking cycle. For example, a bulker of 40,000 DWT with an average fuel consumption of 20 tons per day can consume additional 8 tons per day in Year 4. These numbers can, in CII terms, “downgrade” vessels from rating B to rating D.

Impact of ship hull fouling on GHG emissions Summary of results from published research studies

Shipowners are aware of the impact of ship hull fouling on GHG emissions and have already started taking actions. There is significant push from IMO’s recent short-term measures (EEXI and CII) to reduce emissions. Charterers are increasingly involved in the decision making. They are financing hull coating upgrades as they are also reporting the emissions of their time-charter fleet as part of their logistics operations. This has led in recent years in a wider adoption of high-performance coatings.

[1] Closing the data-financing gap to turbocharge maritime energy efficiency technologies retrofits, Global Centre for Maritime Decarbonisation (GCMD), 2024

[2] Analysing the Impact of Marine Biofouling on the Energy Efficiency of Ships and the GHG Abatement Potential of Biofouling Management Measures, GEF-UNDP-IMO GloFouling Partnerships Project, 2022