Authors Marciel Gaier , Ph.D. Philippos Sfiris

Part 1: Always clean hulls – Part 1: Why keeping the hull clean is important

Part 2: Always clean hulls – Part 2: Hull grooming emerging as a proactive method to manage biofouling

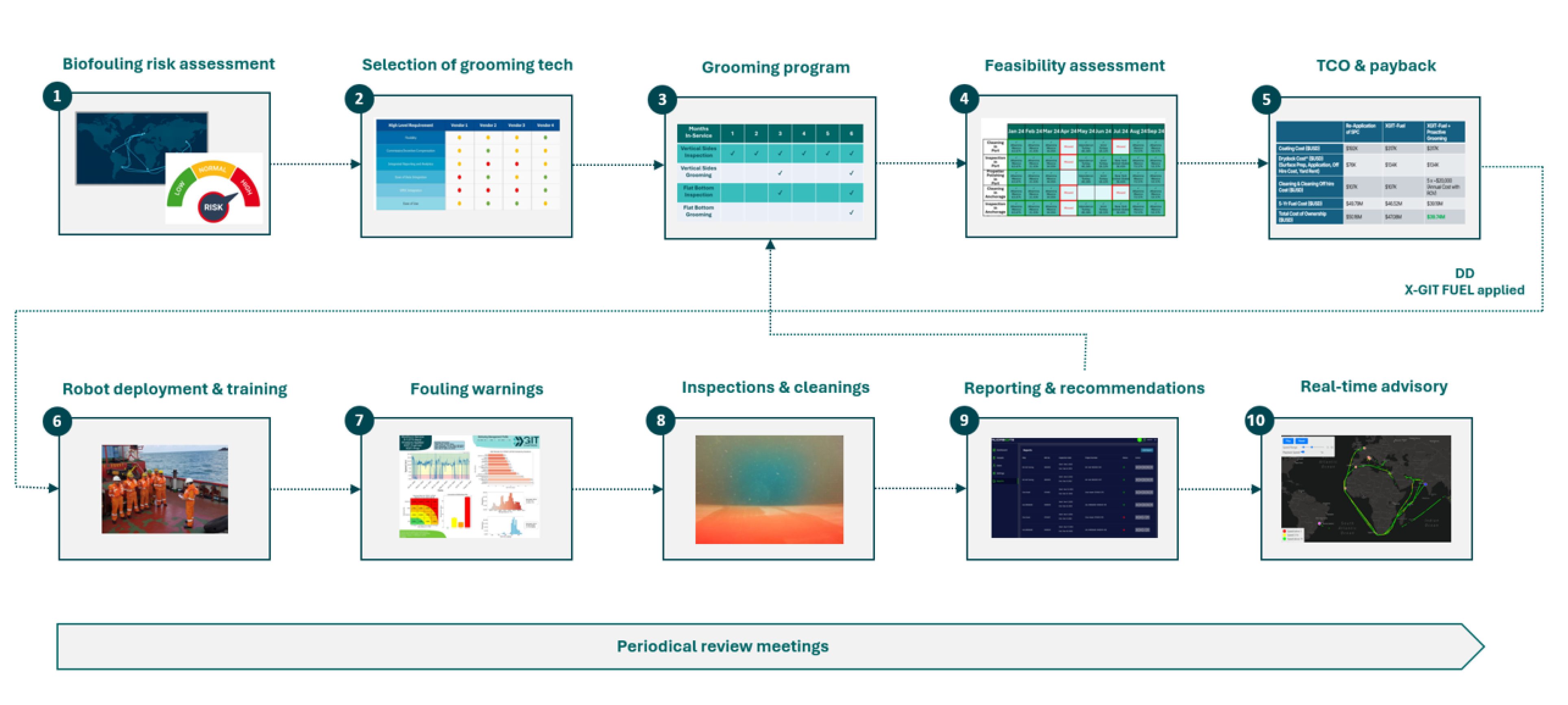

How is a hull grooming program put into practice?

A structured process of implementation includes the following 10 steps:

Hull grooming process

Before paint application – during the evaluation process:

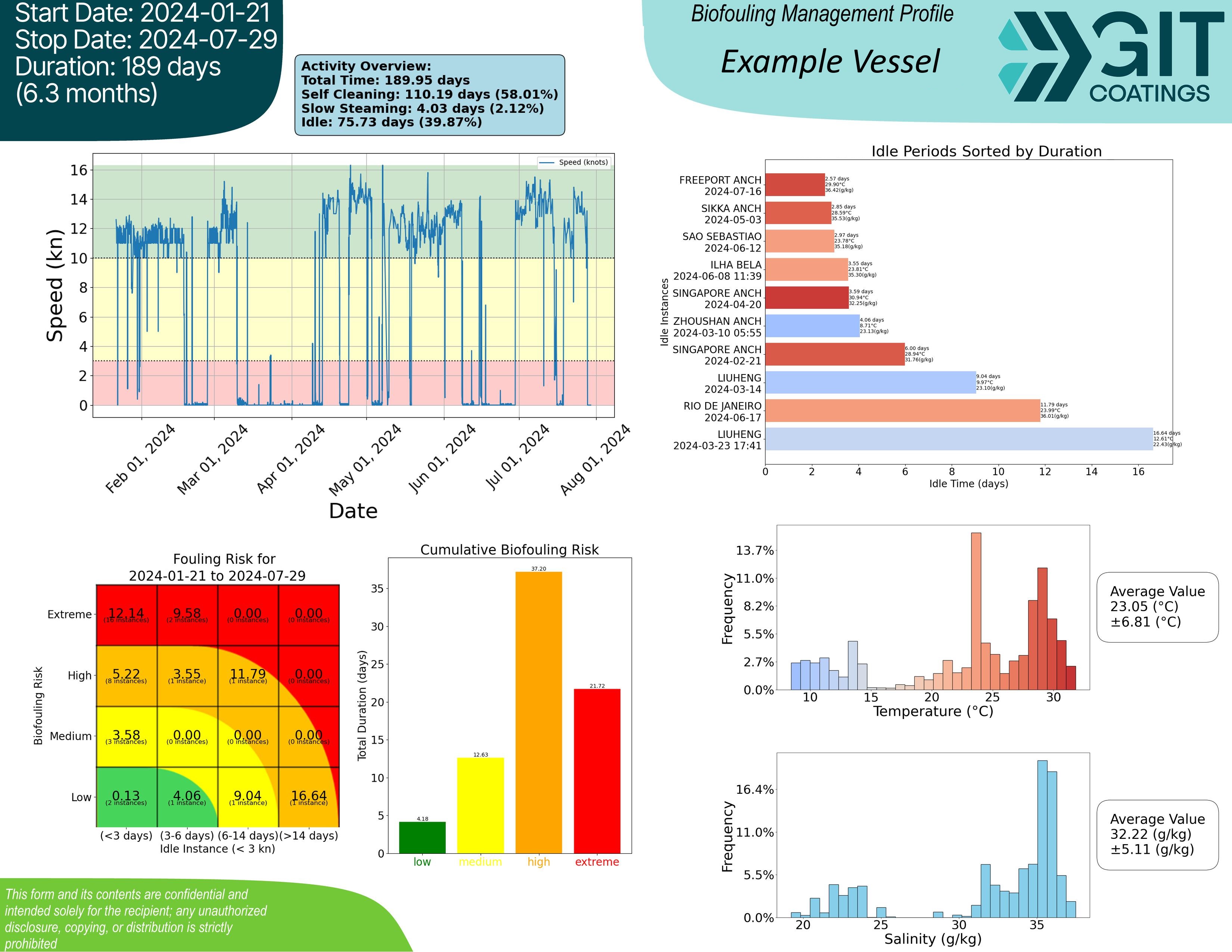

(1) Biofouling risk assessment

Assessing the vessel’s biofouling risk based on historical and expected trading pattern to define the need and frequency of grooming. Fouling risk profile is based on vessel’s operating profile (speed, activity, static periods in high fouling pressure waters, seasonality) by using a combination of AIS and oceanographic data on water temperature and salinity. See example below:

Example of biofouling risk assessment

(2) Selection of grooming technology

Selecting the right technology for the vessel based on a holistic evaluation of the vessel’s operating profile and limitations, the crew’s ‘readiness’ and maturity level as well as the economical aspects (CAPEX and OPEX). Selection process requires an overview of available grooming technologies and expectations for the grooming schedule highlighting the fouling rating that each technology is capable of cleaning.

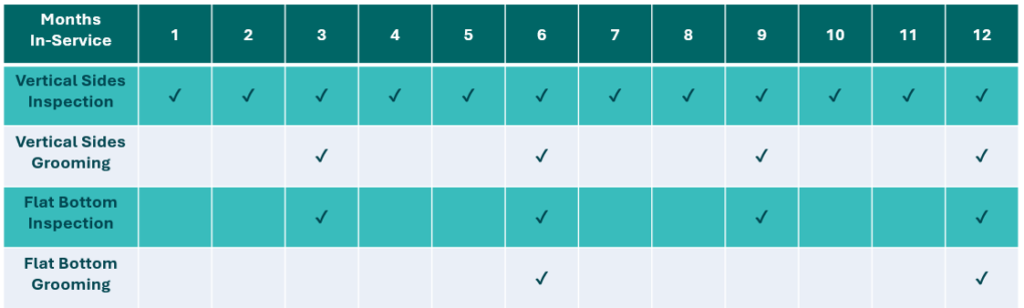

(3) Grooming program

Defining a schedule of inspections and cleanings for vertical sides and flat bottom. Indicate when and where the grooming can take place based on technology: in-transit, at anchorage or in berth. This includes (a) setting the objective & KPIs of the program (for example, maintaining the vertical sides at or below FR 30 – heavy slime as per NSTM Chapter 081) and (b) defining a mitigation plan with service providers in port if robot fails to maintain the proactive cleaning schedule. The grooming program, being a ‘routine’ hull maintenance process, should be part of the vessel’s planned maintenance system

Example of hull grooming schedule

(4) Feasibility assessment

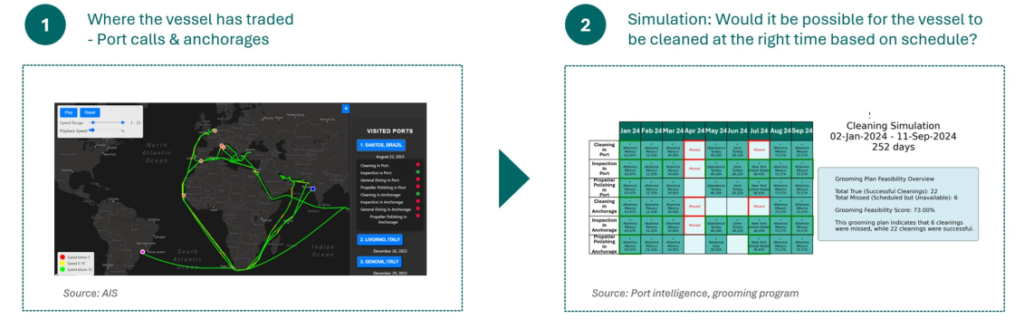

Feasibility assessment of grooming program based on the vessel’s historical trade and time spent in ports and anchorages. See example below:

Example of grooming feasibility assessment

(5) TCO & payback

Total Cost of Ownership (TCO) and payback analysis comparing the hull grooming solution to other alternatives for hull management. Costs include the purchasing cost of paint, shipyard cost including surface preparation and paint application, fuel cost as well as any additional costs of hull cleanings and off-hire.

After paint application:

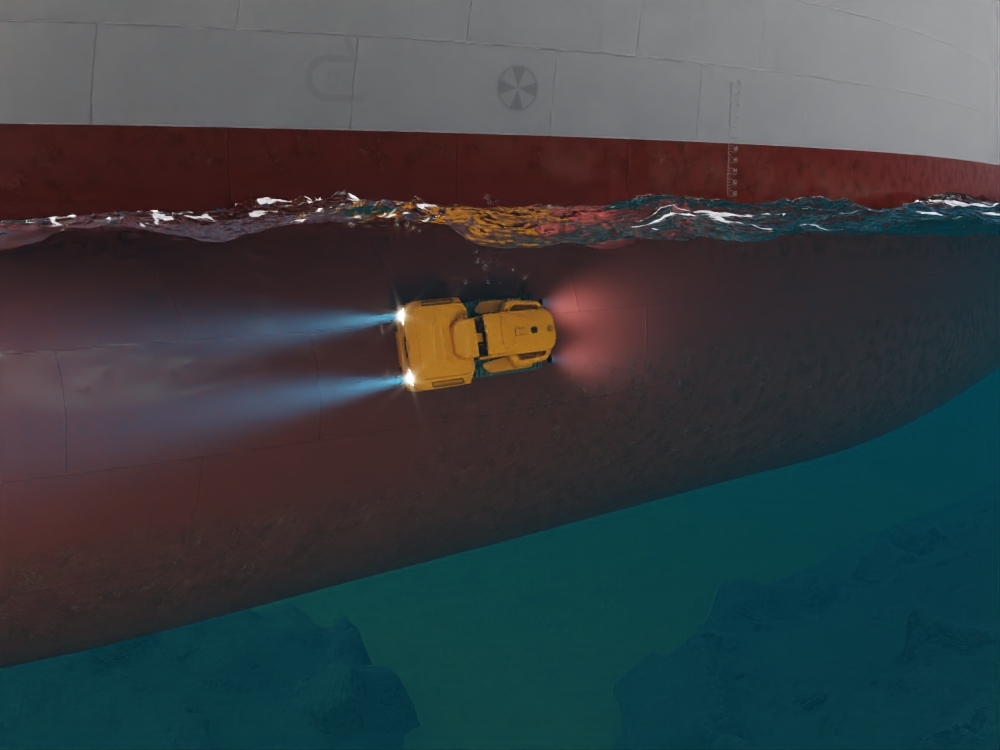

(6) Robot deployment and crew training

Deployment of grooming robot at drydock or at convenient port and crew training by the approved grooming robot vendor.

(7) Fouling warnings

Fouling warnings when vessel is idle in high fouling risk areas as an additional prevention mechanism.

(8) Inspections and cleanings

Reporting of inspections pre and post grooming operations. Footage sharing methods are defined with robot grooming vendor.

(9) Reporting and recommendations

Combining insights from inspections footage and performance monitoring to make recommendations and adjustments to grooming frequency.

(10) Real-time advisory

Real-time advisory based on future port calls and intelligence on port regulatory status.

Submit Below & Receive Full Article

XGIT-GROOM